Technical article

Ice buildup on evaporator

Ice buildup on the evaporator occurs in sub-zero cold when the water contained in the ambient air solidifies and accumulates on the evaporator.

Common causes are overloading the cabinet or cold room, prolonged opening and too high a humidity level.

Impacts include loss of cooling efficiency, fin breakage, loss of goods, handling and costly interventions, sometimes visible in stores.

Prevention is based on anticipated actions such as reducing an overload and triggering a defrost before the incident. A drift tracking tool like ALERT can help you act before icing occurs.

Ice on the evaporator: causes, risks, maintenance, prevention

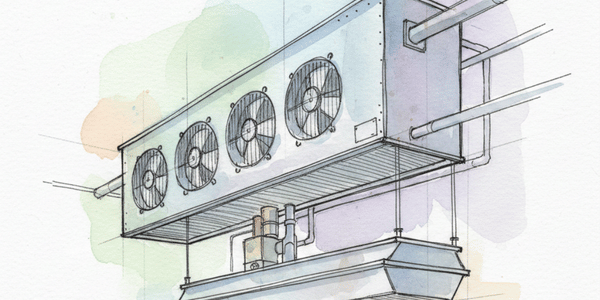

In a negative environment, the water contained in the ambient air solidifies. In industrial refrigeration, this can result in ice forming on the evaporators. The problem is known to specialists and has a common name: icing.

The subject is not only technical. On an operating site, icing can mobilize teams, empty a cabinet or a cold room, generate costly interventions, and then degrade the customer experience when it is seen on the surface.

This page includes a simple and usable method: definition, signs, causes, impacts, maintenance steps and prevention levers, with an action-oriented approach before the incident.

Simple definition

Ice formation is an accumulation of ice on the evaporator in negative cold, linked to the humidity of the air that solidifies. This ice disrupts the heat exchange and can lead to a decrease in cooling efficiency, then material damage and operational impacts.

Field signs that can/should alert

These signs do not prove anything on their own. They help prioritize a check.

• Loss of cooling efficiency

• Recurring difficulties in maintaining temperatures (if observed on site)

• Visible signs of frost or ice around the evaporator (if access and visibility)

• Operational tension related to repeated interventions or areas to be closed

Common causes of icing

• Overloading of the cabinet or cold room

• Prolonged opening of the cabinet or cold room

• Humidity level too high

These causes have one thing in common: they increase the supply of moisture and disrupt the conditions under which the evaporator operates.

Possible consequences on operation

Loss of cooling efficiency

The exchange degrades. Cooling becomes less efficient.

Evaporator fins break

Ice formation can lead to breakage of the fins, with a lasting degradation of the exchange.

Loss of goods

When temperatures are no longer maintained, the risk of loss becomes real.

Handling and downtime

Ice formation leads to handling: emptying, storing, putting back in place. This time is not neutral.

Costly interventions

Refrigeration interventions to water the equipment with hot water are cited as costly.

Store image

Closed aisles, empty furniture, puddles. When this is seen, the impact on the store’s image is direct.

Stress

The cumulative effects create operational stress: urgency, arbitration, losses, customers, refrigeration planning.

Maintenance: what is traditionally done on site

The procedure described is cumbersome because it combines technical and operational aspects.

1. Empty the cabinet or cold room

2. Spray the evaporator with hot water

3. …until the ice melts

4. Clean the water

5. Restart the equipment

6. Re-fill the cabinet or cold room

This kind of operation takes time, work, and creates visible disturbances.

Can we act before the start of the icing? Yes!

Ice formation becomes more problematic when it becomes visible:

When the ice is already installed, maintenance switches to a heavy operation, with emptying, hot water, cleaning and putting back into service.

Our drift and failure prediction service is specifically designed to detect drift before icing, to allow simple actions as long as the incident has not occurred, such as emptying an overload of goods and/or defrosting before the breakdown.

The goal is to reduce situations where we find ourselves closing an area, emptying a display case, managing puddles of water, and depending on an emergency intervention.

If you want to link your operating reality to this framework, we can show you, in a demo and without obligation, what this detection looks like and how it helps to act before the icing.